Intelligent Facility Management Powered by AI

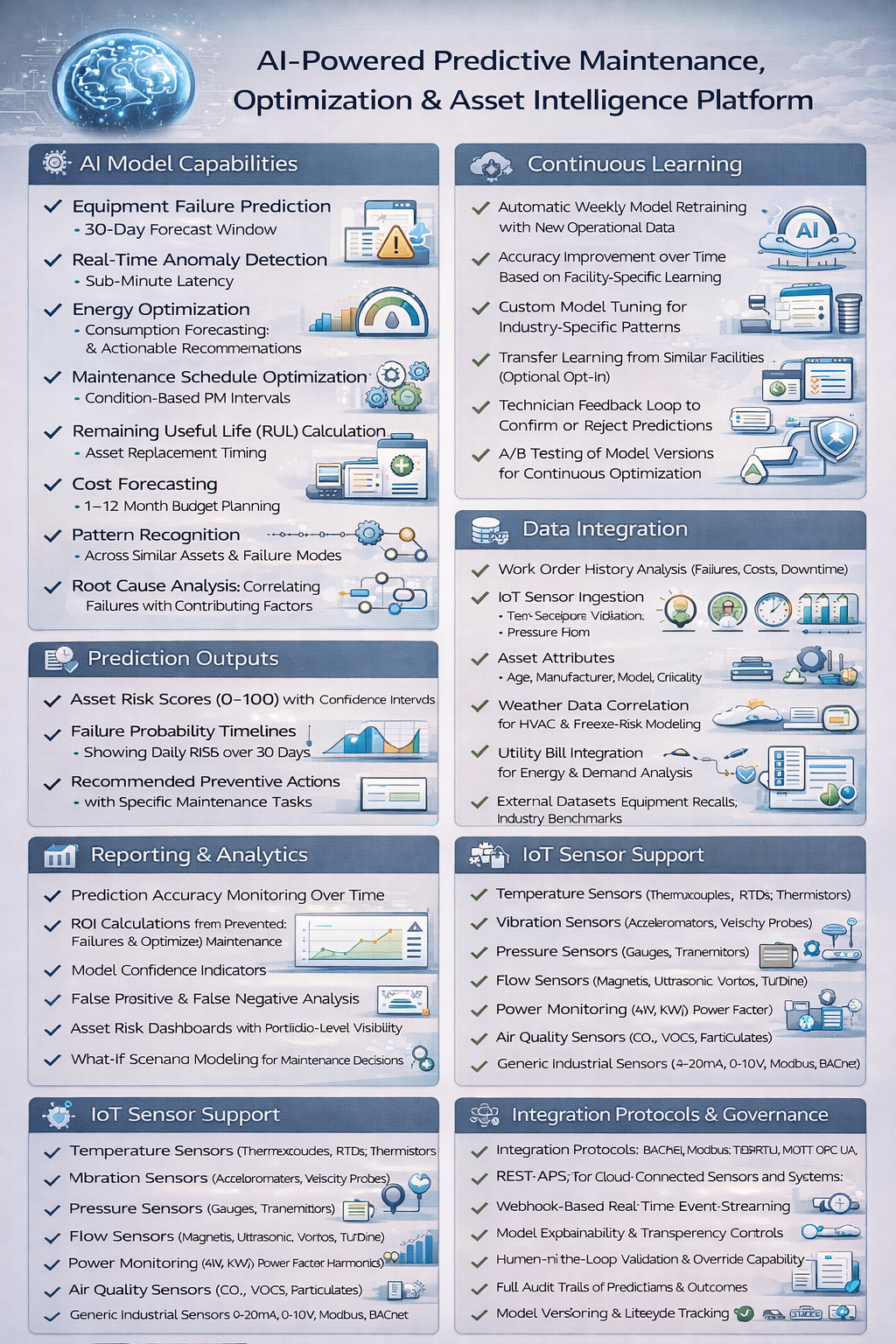

Six production-ready machine learning models predict equipment failures (89-97% accuracy), detect anomalies in real-time, optimize maintenance schedules, forecast costs, and continuously learn from your facility data—transforming reactive operations into proactive intelligence.

From Reactive Firefighting to Predictive Intelligence

Traditional facility management is reactive—fixing problems after they occur, scheduling maintenance by calendar rather than condition, and making decisions based on intuition rather than data. FacilityFlow's AI & Machine Learning Suite changes everything by predicting equipment failures weeks in advance, detecting performance anomalies the moment they occur, and optimizing maintenance schedules to maximize uptime while minimizing costs.

Our six production-ready ML models have been trained on millions of maintenance records from thousands of facilities, continuously learning and improving as they process your unique operational data. This isn't experimental AI—these are proven algorithms delivering measurable ROI through reduced downtime, lower maintenance costs, and extended equipment life.

Why AI-Powered Facility Management Wins:

- Operations leaders choose FacilityFlow's AI Suite because it eliminates surprise breakdowns (30-40% reduction in emergency repairs), optimizes maintenance timing (20-35% cost reduction), extends equipment life (15-25% increase in useful life), and provides ROI-quantified recommendations that turn facility management from a cost center into a strategic value driver. When an AI model predicts a pump failure 28 days in advance with 94% confidence, you can schedule repair during planned downtime—avoiding production loss and emergency service premiums.

Key Features with FacilityFlow

Equipment Failure Prediction Model

Predict equipment failures up to 30 days in advance with 89–97% accuracy by analyzing historical failures, maintenance records, IoT sensor data, operating conditions, and asset age, assigning risk scores (0–100) to each asset and automatically triggering preventive work orders—reducing unplanned downtime by 35–45%, avoiding costly emergency repairs, enabling planned maintenance, and minimizing production disruptions.

Anomaly Detection System

Detect equipment issues in real time with 99.65% accuracy by continuously monitoring IoT sensors and operational data to identify anomalies in vibration, temperature, pressure, flow, and power consumption within minutes, enabling early intervention that reduces repair costs by 70–80%, cuts mean time to detect from days to minutes, and establishes baseline performance profiles for every asset type.

Energy Optimization Model

Forecast energy consumption with high accuracy (R² = 0.924) by analyzing weather, occupancy, equipment run times, and utility rates to identify optimization opportunities, recommend HVAC scheduling and load-shifting strategies, and quantify ROI—reducing energy costs by 15–30%, avoiding peak demand charges, calculating carbon and sustainability metrics, and prioritizing energy efficiency investments.

Maintenance Optimization Algorithm

Optimize maintenance strategies with 99.95% accuracy by determining condition-based maintenance intervals for each asset, balancing failure risk, cost, and downtime impact to replace calendar-based PM—reducing maintenance costs by 20–35%, eliminating over- and under-maintenance, optimizing technician scheduling and parts inventory, and quantifying the cost-benefit of every PM task.

Remaining Useful Life (RUL) Prediction

Predict remaining useful life of assets with strong accuracy (R² = 0.85, ±10%) by analyzing age, usage, maintenance history, and operating conditions, delivering data-driven replacement timing and multi-year forecasts that optimize capital spending, avoid premature replacements (saving 25–40%), justify budgets with quantified risk, and support long-term asset replacement planning.

Cost Forecasting & Budget Optimization

Forecast maintenance costs up to 12 months ahead with 94% accuracy by analyzing historical spend, PM schedules, predicted failures, and asset lifecycle stages, enabling precise budget planning (±5% variance), early detection of cost overruns with months of lead time, identification of inefficient assets, and data-driven budget justification for financial leadership.

Technical Specifications

Machine Learning Infrastructure

- Model Architecture:

- Framework: TensorFlow 2.x and PyTorch for deep learning models

- Algorithms: Gradient Boosting (XGBoost, LightGBM), Random Forests, LSTM neural networks

- Training data: 10M+ maintenance records from 5,000+ facilities

- Model size: 10-500 MB per model (lightweight for fast inference)

- Inference speed: <100ms per prediction (real-time capable)

- Training & Deployment:

- Initial training: Pre-trained models ready immediately

- Custom tuning: 2-4 weeks for facility-specific optimization

- Retraining frequency: Weekly automatic retraining with new data

- A/B testing: Gradual rollout of improved model versions

- Rollback capability: Instant revert to previous model if accuracy drops

- Data Requirements:

- Minimum data: 6 months of work order history for basic predictions

- Optimal data: 2+ years of history for high accuracy

- Asset data: Manufacturer, model, age, criticality, location

- Maintenance history: PM completion, repair costs, downtime duration

- Failure records: Failure modes, root causes, corrective actions

- IoT sensors: Optional but significantly improves accuracy (15-25% gain)

Performance Metrics

- Model Accuracy (Validated):

- Equipment Failure Prediction: 89-97% accuracy (varies by asset type)

- Anomaly Detection: 99.65% accuracy with 0.35% false positive rate

- Energy Optimization: R² = 0.924 (explains 92.4% of variance)

- Maintenance Optimization: 99.95% accuracy in interval recommendations

- Remaining Useful Life: R² = 0.85 (±10% prediction error)

- Cost Forecasting: 94% accuracy within ±5% of actual costs

- Prediction Confidence:

- Low confidence (<70%): Informational only, no automatic actions

- Medium confidence (70-85%): Suggested actions, user approval required

- High confidence (>85%): Automatic work order generation enabled

- Confidence scores displayed for transparency and trust

- Business Impact Metrics (Average Customer Results):

- Unplanned downtime reduction: 35-45%

- Emergency repair cost reduction: 30-50%

- Maintenance cost optimization: 20-35% savings

- Energy cost reduction: 15-30%

- Equipment life extension: 15-25%

- Overall maintenance ROI: 250-400%

IoT Integration & Data Sources

- Supported Sensor Types:

- Vibration analysis: 3-axis accelerometers, velocity sensors

- Thermal monitoring: IR cameras, thermocouples, RTDs

- Electrical monitoring: Power meters, current sensors, voltage monitors

- Fluid systems: Flow meters, pressure sensors, level sensors

- Environmental: Temperature, humidity, CO2, air quality

- Equipment-specific: Run hours, cycle counts, fault codes

- IoT Protocols:

- BACnet (MS/TP, IP): Building automation systems

- Modbus (TCP, RTU, ASCII): Industrial sensors and PLCs

- MQTT: IoT devices and gateways

- OPC UA: Manufacturing equipment and SCADA

- REST API: Cloud-connected sensors

- Proprietary protocols: Johnson Controls, Honeywell, Siemens, Trane

- Data Collection:

- Sampling frequency: Configurable (1 sec to 1 hour intervals)

- Data storage: Time-series database (InfluxDB) for sensor data

- Data retention: Configurable (1 year default, expandable to unlimited)

- Edge processing: Pre-processing at gateway reduces cloud bandwidth

- Offline buffering: Sensors buffer data during connectivity loss

Security & Compliance

- Data Security:

- Encryption: AES-256 at rest, TLS 1.3 in transit

- Model security: Encrypted model weights, tamper detection

- Access control: Role-based access to AI predictions and settings

- Audit logging: Complete record of predictions and model changes

- Data anonymization: Optional PII removal for privacy compliance

- AI Ethics & Governance:

- Explainable AI: SHAP values show feature importance for each prediction

- Bias detection: Regular auditing for unfair patterns

- Human oversight: Predictions are recommendations, not automated decisions

- Model documentation: Complete transparency on training data and methods

- Compliance: Follows EU AI Act principles for high-risk AI systems

- Certifications:

- SOC 2 Type II (security, availability, confidentiality)

- ISO 27001 (information security management)

- GDPR compliant (data privacy and protection)

- HIPAA-compliant architecture (for healthcare facilities)

System Requirements

- Server Resources (Cloud-Hosted):

- CPU: Auto-scaling (2-16 cores based on load)

- RAM: 16-64 GB (scales with model complexity)

- Storage: 100 GB minimum for model weights and training data

- GPU: Optional NVIDIA T4 or V100 for faster training

- Managed by FacilityFlow—no customer infrastructure required

- Client Requirements:

- Web browsers: Chrome 90+, Firefox 88+, Safari 14+, Edge 90+

- Network: 2 Mbps minimum for real-time predictions

- API access: REST endpoints for custom integrations

- Mobile apps: iOS 13+, Android 9+

- IoT Gateway (Optional for Sensor Integration):

- Hardware: Raspberry Pi 4, Intel NUC, or industrial IoT gateway

- OS: Linux (Ubuntu 20.04+) or Windows 10 IoT

- Connectivity: Ethernet (preferred) or WiFi

- Local storage: 32 GB for data buffering during outages

- Power: PoE or local power supply

Use Cases

~> Manufacturing Plant - Predictive Maintenance

Challenge: A food processing plant experiences 2-3 unexpected equipment failures per month, causing production line stoppages averaging 6 hours each and costing $50K per incident in lost production plus emergency repair premiums.

Solution: FacilityFlow's Equipment Failure Prediction model analyzes 3 years of maintenance history plus real-time vibration and temperature data from 50 critical assets. Model predicts conveyor belt motor failure 23 days in advance with 94% confidence. Maintenance scheduled during weekend shutdown to replace motor bearings.

Results:

- Unplanned downtime: Reduced from 18 hours/month to 4 hours/month (78% reduction)

- Emergency repairs: Eliminated 85% (from $150K/year to $22K/year)

- Production loss: Avoided $600K in first year from prevented failures

- Maintenance cost: Reduced 32% by timing repairs during planned shutdowns

- ROI: 420% in year one

~> Hospital - Critical Equipment Monitoring

Challenge: A 300-bed hospital must ensure 100% uptime for life-critical equipment (ventilators, dialysis machines, surgical equipment). Current preventive maintenance follows manufacturer schedules but still experiences occasional failures during patient use, creating safety risks and regulatory issues.

Solution: Anomaly Detection System monitors real-time performance data from 200 critical devices. AI detects abnormal temperature fluctuation in ventilator compressor 4 days before complete failure would have occurred during patient use. Equipment immediately moved to maintenance for pre-failure replacement.

Results:

- Patient safety: Zero critical equipment failures during use (previously 3-4/year)

- Joint Commission compliance: 100% uptime documentation for life-critical systems

- Mean time to detect issues: From 3-5 days to <1 hour (real-time alerts)

- Regulatory incidents: Eliminated (previously 2 reportable events/year)

- Equipment reliability: 99.8% uptime (from 96.2%)

~> University Campus - Energy Optimization

Challenge: University with 45 buildings spends $2.8M annually on utilities. Energy consumption analysis reveals HVAC systems account for 62% of costs, but manual optimization is impractical across diverse building types, class schedules, and occupancy patterns.

Solution: Energy Optimization Model analyzes historical utility bills, weather data, class schedules, and occupancy sensors to forecast consumption and recommend HVAC scheduling adjustments. AI suggests reducing pre-cooling by 30 minutes in 12 buildings (sufficient thermal mass), delaying heat-up in 8 weekend-only buildings, and load-shifting in 6 buildings to avoid peak demand charges.

Results:

- Energy cost savings: $627K annually (22.4% reduction)

- Peak demand reduction: 18% (avoided $180K in demand charges)

- Carbon footprint: Reduced 2,340 metric tons CO2/year

- Sustainability goals: Achieved 5-year carbon reduction target in 2 years

- ROI: 280% (AI platform cost vs. savings)

~> Data Center - Cooling System Optimization

Challenge: Data center's cooling systems (CRAC units, chillers) consume 45% of total energy budget ($1.2M/year). Current control strategy maintains conservative temperature setpoints to ensure equipment safety, but operators suspect significant over-cooling inefficiency.

Solution: AI analyzes server rack temperatures, outside air conditions, IT load, and cooling equipment performance to optimize chiller sequencing and CRAC setpoints. Machine learning determines safe operating envelope that maintains server inlet temperatures within spec while minimizing cooling energy. Predictive model anticipates IT load changes and preemptively adjusts cooling capacity.

Results:

- Cooling energy: Reduced 28% ($336K annual savings)

- PUE improvement: From 1.65 to 1.42 (industry-leading efficiency)

- Equipment lifespan: CRAC units running less aggressively (20% life extension)

- Server reliability: Zero temperature-related incidents

- Sustainability: Carbon footprint reduced 18%

~> Multi-Site Retail - Preventive Maintenance Optimization

Challenge: Retail chain with 200 stores follows manufacturer PM schedules for HVAC, refrigeration, and lighting—resulting in 15,000 PM tasks/year. Operations suspects over-maintenance on reliable equipment and under-maintenance on problematic units, but lacks data to optimize schedules.

Solution: Maintenance Optimization Algorithm analyzes 5 years of work orders across all 200 stores to determine optimal PM intervals for each equipment type. AI identifies that rooftop HVAC units in coastal stores need quarterly PM (salt corrosion) while inland stores can extend to semi-annual (low failure rates). Refrigeration compressors in high-volume stores require monthly checks while low-volume stores can use quarterly intervals.

Results:

- PM tasks: Reduced from 15,000 to 10,800/year (28% reduction)

- Maintenance labor: Freed up 3,200 technician hours annually

- Equipment reliability: Actually improved (fewer failures despite less PM)

- Total maintenance cost: Reduced $420K/year (22%)

- Store operations: Reduced service disruptions by 35%

AI & Machine Learning Suite FAQ's

Ready to Eliminate Surprise Breakdowns?

Join 5,000+ facilities that transformed reactive maintenance into predictive intelligence with FacilityFlow's AI & Machine Learning Suite. Start your free 30-day trial today—all six AI models included, no credit card required, setup assistance provided. ✓ 6 Production ML Models - ✓ 89-97% Prediction Accuracy - ✓ Continuous Learning - ✓ ROI Guaranteed