Stop Reacting to Breakdowns. Start Predicting Them.

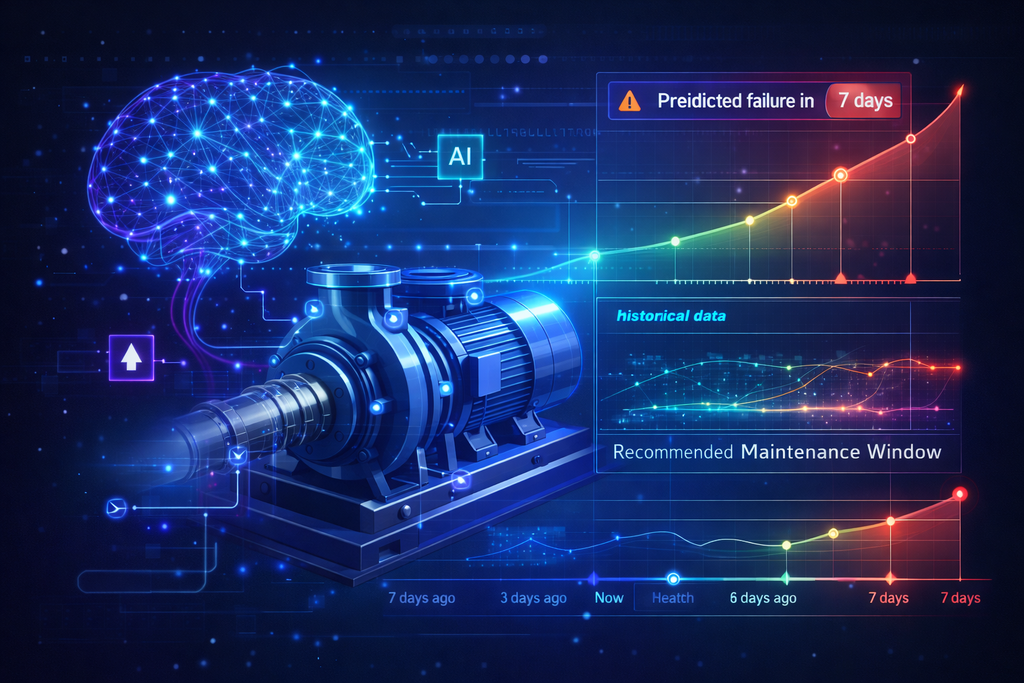

AI-powered machine learning models predict equipment failures 24 hours to 30 days in advance with 89-97% accuracy. Schedule maintenance at optimal times, reduce unplanned downtime by 70%, and extend asset lifespan by 30%—automatically.

Three Simple Steps to Predictive Intelligence

Connect IoT Sensors & Equipment

Install sensors on critical equipment or connect to existing BMS/SCADA systems. FacilityFlow supports 6 protocols (MQTT, OPC-UA, Modbus, BACnet, WebSocket, REST API) and processes 10,000+ messages per second. No complex integration required. Vibration levels and patterns, temperature readings (ambient and internal), pressure measurements, current draw and power consumption, operating hours and cycles, performance metrics and output, any custom sensor data.

AI Models Learn Your Equipment

Machine learning models automatically train on your equipment data, learning normal operating patterns, seasonal variations, and degradation signatures. The more data collected, the more accurate predictions become. No data scientist required. Equipment breakdown prediction model, anomaly detection algorithms, failure pattern recognition, maintenance demand forecasting, cost prediction models, performance optimization models.

Receive Predictions & Optimize Maintenance

Get predictions 7-30 days before failures occur with confidence scores. System automatically generates maintenance work orders during optimal windows, preventing emergency repairs and scheduling maintenance when it causes least disruption. Failure alerts with confidence scores (85-99%), auto-generated work orders with scheduling, parts reservation and ordering, technician assignment based on skills, notification to stakeholders, calendar optimization for minimal disruption.

How AI Predictive Maintenance Changes Everything

Six Production Machine Learning Models

Enterprise-grade AI models working together to keep your equipment running

🔴Equipment Breakdown Prediction: [Accuracy: 89-97%]

Description: Predicts equipment failures 7-30 days in advance by analyzing operating patterns, sensor data, maintenance history, and environmental factors. Identifies specific failure modes (bearing failure, seal degradation, motor burnout, etc.) with confidence scores.

How It Works:

- Analyzes 50+ data points per equipment

- Compares current behavior vs. historical patterns

- Identifies degradation signatures

- Predicts specific failure modes

- Provides confidence score (85-99%)

- Recommends optimal maintenance window

Input Data: Vibration, temperature, pressure, current draw, operating hours, maintenance history, environmental conditions, performance metrics.

Output: Motor HVAC-001 has 94% probability of bearing failure within 14 days. Recommended action: Replace bearings during Jan 10-12 maintenance window.

🔍 Real-Time Anomaly Detection: [Accuracy: 92-96%]

Description: Continuously monitors equipment behavior in real-time and alerts on anomalies that deviate from normal operating patterns—even if they don't immediately indicate failure. Catches issues before they become critical.

How It Works:

- Establishes baseline "normal" behavior for each asset

- Detects deviations from normal patterns

- Filters out false positives

- Ranks anomalies by severity

- Triggers alerts for investigation

- Learns and adapts to operational changes

Anomaly Types Detected: Unexpected temperature spikes, unusual vibration patterns, abnormal pressure fluctuations, erratic performance, irregular current draw, unexpected shutdowns

Output: Anomaly detected: Pump PUMP-024 vibration increased 35% above baseline. Severity: Medium. Investigate within 48 hours to prevent potential failure.

📈 Maintenance Demand Forecasting: [Accuracy: 85-91%]

Description: Predicts future maintenance workload and resource requirements by analyzing seasonal patterns, equipment age profiles, historical maintenance demand, and operational schedules. Helps optimize staffing, parts inventory, and budgeting.

How It Works:

- Analyzes historical maintenance patterns

- Identifies seasonal variations

- Accounts for equipment age and lifecycle

- Factors in planned production schedules

- Predicts parts and labor requirements

- Forecasts budget needs

Forecasting Periods:

- Weekly maintenance demand

- Monthly workload projections

- Quarterly staffing requirements

- Annual budget forecasting

Output: Predicted maintenance demand for Q1 2025: 847 work hours, $42,300 parts budget. Peak period: Mid-February (HVAC seasonal maintenance). Recommend 2 additional technicians.

⚙️ Maintenance Schedule Optimization: [Accuracy: 88-93%]

Description: Optimizes maintenance schedules by finding the perfect balance between equipment condition, operational schedules, resource availability, and cost. Automatically reschedules PM based on actual equipment health instead of fixed calendars.

How It Works:

- Analyzes equipment health scores

- Considers production schedules

- Evaluates resource availability

- Calculates optimal maintenance windows

- Balances cost vs. risk

- Dynamically adjusts PM schedules

Optimization Factors: Equipment criticality, current health score, failure probability, production impact, labor availability, parts availability, cost considerations.

Output: PM for COMP-015 can be safely delayed from Jan 5 to Jan 18 based on health score (92/100). Rescheduling saves $1,200 in overtime costs with minimal risk increase.

💰 COST PREDICTION: [Accuracy: 84-89%]

Description: Predicts future maintenance costs by analyzing historical spending patterns, equipment age, failure rates, and operational intensity. Helps with accurate budgeting and identifies cost optimization opportunities.

How It Works:

- Analyzes historical cost data

- Factors in equipment aging curves

- Considers operational intensity

- Predicts failure-related costs

- Identifies cost drivers

- Recommends cost reduction strategies

Cost Categories Predicted: Preventive maintenance costs, corrective repair costs, emergency repair costs, parts expenditure, labor costs, downtime costs, total cost of ownership

Output: Predicted 2025 maintenance costs for Building A: $287,000 (±8%). Major drivers: HVAC system aging (60%), pump repairs (25%). Recommend HVAC replacement in Q3 to reduce costs 40% in subsequent years.

🔄 Failure Pattern Recognition: [Accuracy: 90-95%]

Description: Identifies recurring failure patterns across similar equipment and root causes. Learns from every failure to improve predictions and prevent similar issues on other assets. Enables systemic improvements.

How It Works:

- Analyzes failure history across asset fleet

- Identifies common failure modes

- Correlates failures with operating conditions

- Recognizes root cause patterns

- Predicts similar failures on related equipment

- Recommends preventive actions

Pattern Types Identified: Recurring failure modes, common root causes, environmental triggers, operational factors, design weaknesses, vendor/model-specific issues

Output: Pattern detected: 4 of 6 Grundfos CR64 pumps failed due to bearing wear at ~12,000 operating hours. Recommend proactive bearing replacement at 11,000 hours for remaining pumps to prevent failures.

See Predictive Maintenance in Action

Real Results from Real Companies

CASE STUDY 1: MANUFACTURING

- Company: `Large Auto Parts Manufacturer`

- Industry: Manufacturing

- Equipment: 500+ production machines

- Challenge: Experiencing 15-20 unplanned equipment failures per month, causing production delays and customer delivery issues. Reactive maintenance costing $1.2M annually in emergency repairs and lost production.

- Solution: Deployed FacilityFlow Predictive Maintenance with IoT sensors on all critical production equipment. ML models trained on 3 months of historical data and began making predictions.

- Results:

- ✅ 72% reduction in unplanned downtime (20 → 5.6 failures/month)

- ✅ $840,000 annual savings in maintenance costs

- ✅ 94% prediction accuracy for motor failures

- ✅ 31% increase in equipment lifespan

- ✅ Zero production line stoppages in Q4

- ✅ ROI achieved in 4.2 months

Quote: The AI predictions are remarkably accurate. We've gone from constant firefighting to proactive maintenance. Our production manager says it's like having X-ray vision into our equipment. ~ Director of Maintenance Operations

CASE STUDY 2: HEALTHCARE

- Company: `Regional Hospital System`

- Industry: Healthcare

- Equipment: Critical facility infrastructure (HVAC, generators, medical gas)

- Challenge: Cannot afford downtime on life-safety equipment. Previous HVAC failure resulted in ICU evacuation costing $2.3M. Needed to prevent failures while maintaining patient safety and regulatory compliance.

- Solution: Implemented predictive maintenance for all critical infrastructure. 24/7 monitoring with real-time anomaly detection. Automated alerting for any equipment degradation.

- Results (18 months):

- ✅ Zero critical equipment failures

- ✅ 89% prediction accuracy for HVAC systems

- ✅ $430,000 savings from prevented failures

- ✅ 100% regulatory compliance maintained

- ✅ 45% reduction in emergency maintenance calls

- ✅ Peace of mind for facility management

Quote: Patient safety is our #1 priority. Predictive maintenance gives us confidence that our critical systems will perform when needed. The early warnings have prevented several potential disasters. ~ VP of Facilities & Engineering

CASE STUDY 3: COMMERCIAL REAL ESTATE

- Company: `Property Management Portfolio`

- Industry: Commercial Real Estate

- Equipment: 15 buildings, 200+ assets (HVAC, elevators, generators)

- Challenge: Tenant complaints about HVAC failures. High maintenance costs from reactive repairs. Need to optimize CapEx planning for equipment replacements across portfolio.

- Solution: Rolled out predictive maintenance across all properties. Portfolio-wide monitoring and predictive analytics. Centralized visibility into equipment health across all buildings.

- Results (24 months):

- ✅ 68% reduction in tenant HVAC complaints

- ✅ $670,000 savings from optimized maintenance

- ✅ 28% longer average equipment lifespan

- ✅ Better CapEx planning with 3-year predictions

- ✅ 92% tenant satisfaction (up from 76%)

- ✅ Increased property valuations

Quote: We can now predict when equipment across our entire portfolio needs attention. This has transformed our maintenance budget from reactive to strategic. Our tenants are happier, our buildings run better. ~ VP of Property Management

Works With Your IoT Infrastructure

Support for 6 protocols. Process 10,000+ messages/second. Connect any sensor or building system.

📡 MQTT

A lightweight publish–subscribe protocol designed for IoT sensors, making it ideal for battery-powered devices and wireless sensor networks used for remote monitoring, environmental sensing, temperature tracking, and vibration analysis.

🏭 OPC-UA

An industry-standard protocol for industrial automation that enables seamless integration with PLCs, SCADA systems, and manufacturing equipment across production lines, CNC machines, robotics platforms, and process control environments.

⚡Modbus TCP/RTU

A legacy industrial communication protocol used to connect existing equipment, with support for both Modbus TCP over Ethernet and Modbus RTU over serial, commonly deployed across legacy machinery, energy meters, motor controllers, PLCs, and industrial instruments.

🏢 BACnet

A building automation standard used for integrating HVAC, lighting, access control, and fire safety systems, enabling centralized monitoring and control across building automation environments.

🔄 WebSocket

A real-time, bidirectional communication mechanism designed for streaming high-frequency sensor data, enabling live dashboards, continuous monitoring, streaming analytics, and instant notifications.

🔌 REST API

A standard HTTP-based API used for cloud-connected sensors and third-party integrations, enabling seamless connectivity with weather services, utility APIs, SaaS platforms, and custom applications.

Performance Metrics (Below protocols)

Real results from real customers

Messages/Second

Processing capacity

Simultaneous

Sensor streams

Average latency

Real-time processing

Uptime

Enterprise reliability

Based on 2024 customer survey of 250+ companies

Start Predicting Failures in Just 4 Weeks

From assessment to live AI-driven predictions with minimal disruption

Assess Equipment and Plan Deployment

We identify critical equipment, assess your existing sensor and system landscape, define success metrics, and configure FacilityFlow for your environment. This step establishes a clear monitoring strategy and deployment plan tailored to your operational goals.

Install Sensors and Connect Systems

IoT sensors are installed on priority assets and connected to FacilityFlow along with existing BMS, SCADA, or PLC systems. Data collection parameters are configured, connectivity is validated, and baseline operating conditions are established.

Train AI Models and Go Live

Machine learning models learn normal equipment behavior using live and historical data, calibrate prediction thresholds, and validate accuracy. Within weeks, teams receive real-time failure predictions, automated work orders, and performance dashboards that continuously improve over time.

Predictive Maintenance FAQ

Stop Reacting. Start Predicting.

Join the companies reducing downtime by 70% with AI-powered predictive maintenance