Universal IoT & Sensor Integration for Smart Facility Management

Connect any sensor, device, or building automation system with FacilityFlow's universal IoT platform. Support for 6 industry-standard protocols, real-time data processing at 10,000+ messages per second, and automated actions based on sensor dataâ€"no vendor lock-in, no integration nightmares.

Break Free from Vendor Lock-In with Universal IoT Integration

- Most facility management systems force you to buy their proprietary sensors and hardware at inflated prices. FacilityFlow takes the opposite approach: we support every major industrial IoT protocol, allowing you to use any sensor from any manufacturer.

- Whether you're monitoring HVAC systems with BACnet, connecting industrial equipment via Modbus, tracking energy consumption through smart meters, or deploying custom sensors via MQTT, FacilityFlow handles it all in one unified platform.

- Our IoT engine processes real-time data from thousands of sensors simultaneously, triggering automated work orders, sending instant alerts, and feeding predictive AI models that prevent equipment failures before they happen.

The Numbers Speak for Themselves

Real results from real customers

Messages Per Second

Real-time data processing capacity

Supported Protocols

MQTT, OPC-UA, Modbus, BACnet, REST, WebSocket

Uptime Guarantee

Enterprise-grade reliability for critical monitoring

Connected Device Types

Supports a wide range of industrial sensors and equipment

Based on 2024 customer survey of 250+ companies

Why FacilityFlow's IoT Integration Stands Apart

No Vendor Lock-In: Use Any Sensor, Any Brand

FacilityFlow supports industry-standard protocols, letting you choose sensors by performance and price, mix brands freely, and integrate with existing BMS and SCADA systems. Supported protocols include MQTT (cloud IoT), OPC-UA (industrial equipment), Modbus RTU/TCP (legacy devices), BACnet (HVAC/building automation), REST API (custom integrations), and WebSocket (real-time communication).

Lightning-Fast Data Processing with Sub-100ms Latency

Our IoT engine processes 10,000+ sensor messages per second in real time, delivers critical alerts in under 100ms, buffers 30 days of offline data, provides automatic failover, and ensures AES-256 encryption and SOC 2 Type II certified security for all data.

Intelligent Automation: From Sensor Data to Action in Seconds

Automatically act on sensor data with custom rules to trigger work orders, send multi-channel alerts, adjust equipment, or escalate issues. Supports complex AND/OR logic, time-based rules, multi-threshold triggers, Python scripting, BMS integration, and maintains an audit trail of all automated actions.

Feed Predictive AI with Rich Sensor Data

FacilityFlow’s predictive maintenance AI uses IoT sensor data to monitor temperature, vibration, pressure, and more, detecting subtle patterns that signal equipment issues weeks before failure. Six ML models analyze data continuously with 89–97% accuracy, provide early warnings 3–30 days in advance, detect anomalies, learn baselines automatically, and track ROI for predictive programs.

Comprehensive Protocol Support for Every Use Case

📡 MQTT (Message Queuing Telemetry Transport)

MQTT is a lightweight pub/sub protocol for cloud IoT sensors, battery-powered devices, and distributed networks. Supports MQTT v3.1.1/v5.0, QoS 0–2, TLS/SSL encryption, retained messages, last will, and wildcard subscriptions. Commonly used for smart building sensors, environmental monitoring, asset tracking, battery-powered devices, and cloud IoT integration (AWS IoT, Azure IoT Hub).

🏭 OPC-UA (Open Platform Communications)

OPC-UA (Open Platform Communications) is a standard protocol for industrial automation, connecting PLCs, SCADA systems, and manufacturing equipment. Supports binary/XML encoding, session-based communication, security modes, browse/read/write/subscribe operations, and complex data types. Used for equipment monitoring, PLC/SCADA integration, manufacturing sensors, and process automation.

🖧 Modbus RTU/TCP

Widely used for legacy industrial equipment, energy meters, and HVAC controllers. Supports serial (RTU) and Ethernet (TCP), function codes 01–06 & 15–16, master/slave architecture, and multiple slave devices. Commonly used for energy meters, HVAC controllers, temperature controllers, legacy equipment, and power monitoring systems.

🌡️ BACnet (Building Automation and Control Networks)

Standard protocol for building automation, connecting HVAC, lighting, access control, and other building systems. Supports BACnet/IP and MSTP, object types (analog/binary input/output), read/write/subscribe services, and Change of Value (COV) notifications. Used for HVAC integration, BMS, lighting control, access control, and energy management.

💻 RESTful API (HTTP/HTTPS)

Web API for custom integrations, third-party systems, and modern IoT devices. Supports REST architecture, JSON payloads, OAuth2/API key authentication, webhooks, and rate limiting. Commonly used for custom sensor integrations, SaaS connectivity, web-based IoT devices, mobile apps, and third-party system integration.

🛰️ WebSocket (Bi-directional Real-Time)

Persistent protocol for real-time, bi-directional communication. Supports full-duplex messaging, auto-reconnection, secure WSS connections, and binary/text frames. Used for live dashboards, real-time equipment monitoring, instant alerts, bidirectional control, and streaming sensor data.

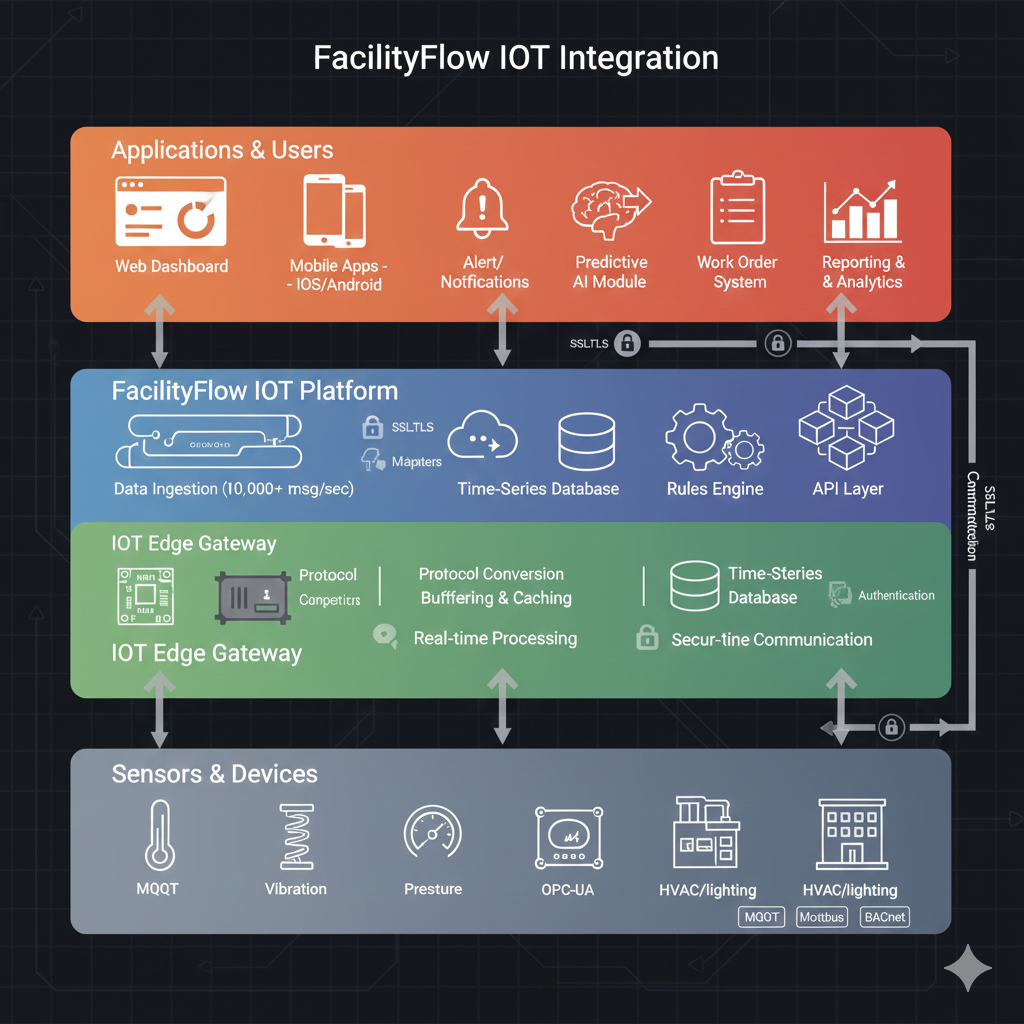

How IoT Integration Works in FacilityFlow

Step-by-Step Process Description:

Step 1: Sensor Data Collection:

- Sensors continuously monitor equipment and environmental conditions, transmitting data via their native protocol (MQTT, Modbus, BACnet, etc.). Data is sent to on-premise edge gateways or directly to the cloud depending on your network architecture.

Step 2: Protocol Conversion & Edge Processing:

- Edge gateways convert proprietary protocols to standard formats, perform local data buffering during network outages, and can execute time-critical edge logic before sending data to the cloud.

Step 3: Cloud Data Ingestion:

- FacilityFlow's IoT platform receives sensor data via secure encrypted connections, processes 10,000+ messages per second, and stores time-series data in high-performance databases optimized for sensor data queries.

Step 4: Rules Engine & Automation:

- Incoming sensor data is evaluated against user-defined rules. When thresholds are exceeded or patterns detected, automated actions are triggered: work orders created, alerts sent, equipment adjusted, or ML models activated.

Step 5: Visualization & Analysis:

- Real-time and historical sensor data appears instantly in dashboards, feeds predictive AI models, generates reports, and integrates with maintenance workflows—creating a closed-loop intelligent facility management system.

Real-World IoT Applications Across Industries

🏭 Predictive Maintenance for Production Equipment:

Scenario: A food processing facility uses FacilityFlow to monitor 150+ motors, pumps, and conveyor systems via vibration and temperature sensors connected through Modbus TCP.

Implementation:

- Vibration sensors on critical motors (Modbus RTU)

- Temperature probes in refrigeration units (MQTT)

- Energy meters on production lines (Modbus TCP)

- PLC integration for production data (OPC-UA)

Results:

- 47% reduction in unplanned downtime

- Early failure detection 14 days in advance

- $230K annual maintenance cost savings

- 99.2% equipment availability achieved

🏢 Smart Building Energy Optimization:

Scenario: A 500,000 sq ft office tower integrates existing BACnet HVAC systems with new IoT sensors to optimize energy consumption and tenant comfort.

Implementation:

- BACnet integration with existing BMS (50+ HVAC units)

- MQTT temperature/humidity sensors in 200+ rooms

- Energy submeters via Modbus (electricity, water, gas)

- Occupancy sensors for lighting control (REST API)

Results:

- 28% reduction in energy costs ($180K annually)

- Automated HVAC adjustments based on occupancy

- Real-time tenant comfort monitoring

- ISO 50001 energy certification achieved

🏥 Medical Equipment & Environment Monitoring:

Scenario: A multi-building hospital campus monitors critical medical equipment, cold storage, and environmental conditions to ensure patient safety and regulatory compliance.

Implementation:

- Temperature monitoring in pharmacies and blood banks (MQTT)

- Medical equipment status tracking (REST API)

- HVAC monitoring for operating rooms (BACnet)

- Emergency generator monitoring (Modbus)

Results:

- 100% compliance with CDC cold chain requirements

- Zero vaccine/medication losses due to temperature excursions

- Automated alerting for critical equipment failures

- Complete audit trail for regulatory inspections

🖥️ Environmental & Equipment Monitoring:

Scenario: A colocation data center monitors environmental conditions, power distribution, and cooling systems to maintain 99.99% uptime SLA.

Implementation:

- Temperature/humidity sensors throughout facility (MQTT)

- UPS and PDU monitoring (Modbus TCP)

- CRAC unit integration (BACnet)

- Water leak detection sensors (MQTT)

Results:

- 99.99% uptime maintained

- 15-minute advance warning of cooling failures

- $500K prevented by early leak detection

- Energy efficiency improved by 18%

Enterprise-Grade IoT Platform Specifications

- Data Ingestion

- Message Throughput: 10,000+ messages per second

- Latency: < 100ms for critical alerts

- Concurrent Connections: Up to 50,000 simultaneous sensors

- Data Retention: Configurable (default: 2 years)

- Supported Protocols

- MQTT: v3.1.1, v5.0 (QoS 0/1/2, TLS/SSL)

- OPC-UA: Binary/XML encoding, all security modes

- Modbus: RTU (RS-485/232), TCP/IP

- BACnet: BACnet/IP (UDP), MSTP (serial)

- REST API: JSON over HTTPS, OAuth 2.0

- WebSocket: WSS (secure), full-duplex

- Data Storage

- Database: Time-series optimized (InfluxDB)

- Compression: Automatic (10:1 ratio typical)

- Querying: SQL-like query language

- Aggregations: Min/max/avg/sum, custom functions

- Security

- Encryption in Transit: TLS 1.2/1.3 (AES-256)

- Encryption at Rest: AES-256

- Authentication: OAuth 2.0, API keys, cert-based

- Network Isolation: VPN, private subnet support

- Compliance: SOC 2 Type II, ISO 27001

- Automation & Rules

- Rule Types: Threshold, pattern, time-based, complex logic

- Actions: Work orders, alerts, API calls, equipment control

- Scripting: Python for custom logic

- Notification Channels: Email, SMS, push, Slack, webhooks

- API & Integration

- REST API: 200+ endpoints

- Rate Limits: 1000 requests/minute (configurable)

- Webhooks: Outbound for events

- SDK: Python, JavaScript, Java

- High Availability

- Uptime SLA: 99.9% guaranteed

- Redundancy: Multi-zone deployment

- Failover: Automatic (< 30 seconds)

- Backup: Daily automated, 30-day retention

- Edge Computing

- Edge Gateways: Raspberry Pi, industrial gateways

- Offline Operation: 30-day data buffering

- Edge Processing: Local rules, filtering, aggregation

- Sync: Automatic when connection restored

Deploy IoT Integration in 3 Simple Steps

Choose Your Protocol & Connect

Select your sensor protocol (MQTT, OPC-UA, Modbus, BACnet, REST, WebSocket) using the configuration wizard to add endpoints, set authentication, and test connections. Includes protocol selection, connection testing, sample configurations for popular sensors, and technical support for complex integrations. Most sensors connect in under 5 minutes.

Set Thresholds & Actions

Create automated rules with our visual rule builder or custom Python scripts. Define sensor conditions to trigger actions like work orders, alerts, equipment adjustments, or event logging. Includes visual builder, pre-built templates, Python scripting, and simulation mode to safely test rules.

Visualize Data & Refine

View real-time sensor data on customizable dashboards, analyze historical trends, monitor automation effectiveness, and optimize your IoT strategy. Includes real-time dashboards, trend analytics, alert effectiveness reports, and ROI tracking.

IoT Integration FAQs

IoT Powers These FacilityFlow Features

Ready to Connect Your Sensors?

Start your free 30-day trial and connect your first sensors in minutes. No credit card required. Implementation support included.